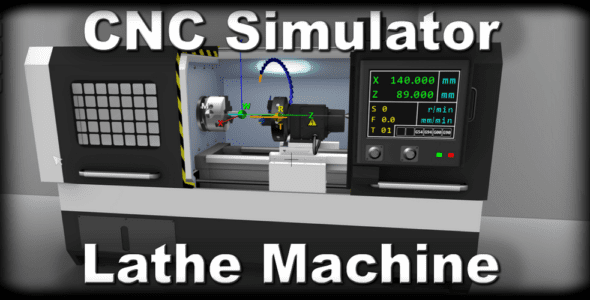

CNC Simulator Lite 1.1.10 Apk + Mod for Android

updateUpdated

offline_boltVersion

1.1.10

phone_androidRequirements

4.1

categoryGenre

Apps, Education & Curriculum

play_circleGoogle Play

The description of CNC Simulator Lite

Introduction to CNC Lathe Simulation Software

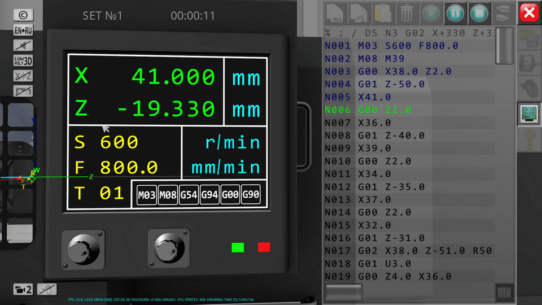

A software simulator for a numerical control (CNC) lathe serves as an educational tool designed to introduce novice machine building specialists to the fundamentals of programming parts turning operations using standard GM code (Fanuc System A).

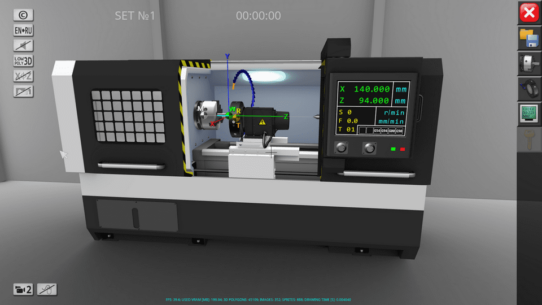

Overview of the Simulation Model

The three-dimensional simulation model is based on a traditional lathe configuration, featuring:

- A CNC system

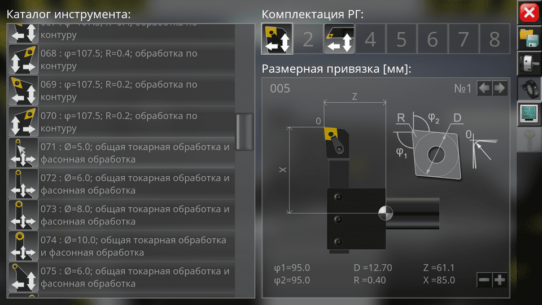

- An eight-position turret

- A three-jaw chuck

- A tailstock

- A coolant supply system

- Various other machinery components

Material processing is conducted on two axes within a horizontal plane, providing a realistic representation of lathe operations.

Field of Application

This software product is primarily utilized in educational settings that incorporate computer technology, including:

- Laboratory lessons for students in computer classes

- Distance learning programs

- Demonstration support for lecture materials across various training areas and specialties, such as:

- Metallurgy

- Engineering

- Material Processing

Key Features of the Simulator

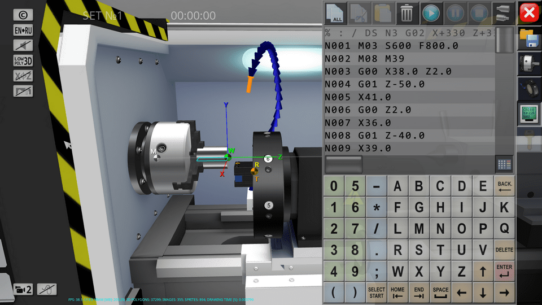

The simulator offers a wide range of functionalities, including:

- Preparation of control program texts for turning operations in standard GM code format

- Syntax and technological error checking for control programs

- Three-dimensional graphical modeling of the main components of the lathe machine and metal-cutting tools

- Simulation of the metal turning process

- Three-dimensional visualization of part formation during turning based on compiled control programs

- Visualization of toolpaths

- Interactive user interaction with the simulation model of technological equipment

Conclusion

By utilizing this CNC lathe simulator, students and novice machine builders can gain valuable insights into the programming and operational aspects of turning metal, enhancing their educational experience in the fields of metallurgy, engineering, and material processing.

What's news

Added support for GoogleAPI version 31.

Download CNC Simulator Lite

Download the complete installation file of the program with a direct link - 28 megabytes.

.apk